KEWO is a Chinese top manufacturer of AC drives, variable speed drive, Solar Pump drive,Soft Stater, Speed Controller...

Tel:86-0755-84186866,

MP:86-18038034988

Mail:service@kewoinverter.com Skye:gary.yu88

Tel:86-0755-84186866,

MP:86-18038034988

Mail:service@kewoinverter.com Skye:gary.yu88

Product center -->Index > Solar Pumps System > DC Voltage Booster > DC voltage booster for increase DC voltage

DC voltage booster for increase DC voltage

DC Voltage booster-low voltage input and high voltage output

It is use to booster low voltage input to high voltage to meet solar pumps system application which need high voltage using.For example, For 1/3 phase 220VAC pumps, it should be request Vmp ( working voltage) is 310VDC, Voc ( open loop voltage) is 350VDC.

For 3 phase 380VAC pumps, it should be request Vmp 540VDC, and Voc 620VDC.

To order to get high voltage output from solar panels, we always connect solar panels in serial.

for 37voc solar panels, we need do 10 pcs solar panels connection in serial to get 370VDC, and need do 17 pcs solar panels connection in serial to get 629VDC.

And it will cause big investment for small power solar pumps system, and also make it difficult to promote this very good green energy solar pump system solution for people who need more water but less of grid power.

We design and develop DC voltage booster device for increase low voltage to high voltage for save solar panels using,for money save.

There are two models DC voltage booster can help us reduce solar panels investment.

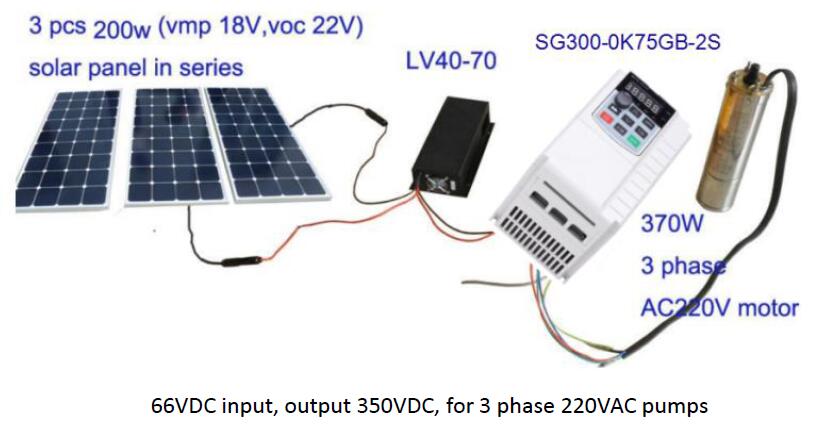

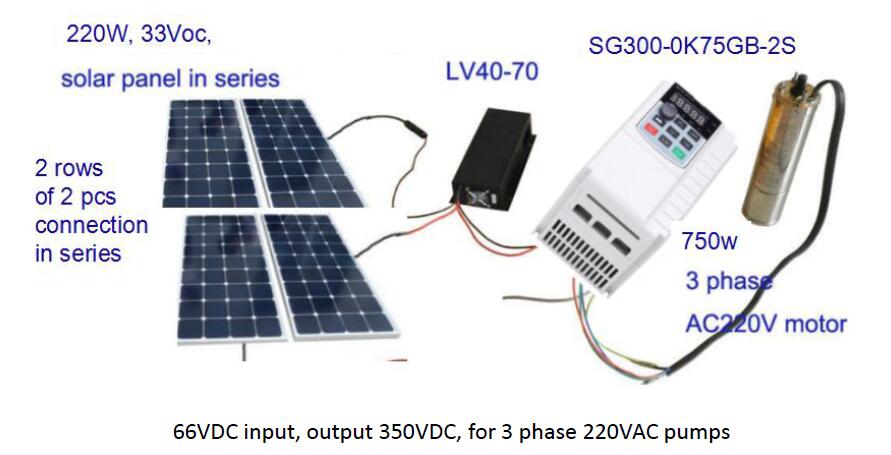

LV40-70 design for "L" (3phase 220Vac) inverter, input voltage range :40 to 70Vdc. 1.5kw

Output will be 240V to 420VDC.

LV60-90 design for"H" (3phase 380Vac) inverter, input voltage range :60 to 90Vdc. 1.5kw

Output will be 480VDC to 720VDC.

Low voltage booster device is specially for small power solar pump inverter with low current and high voltage, especial for 0.75kw, 1.5kw 220V pumps, and 0.75kw, 1.5kw 380V pumps. Input voltage is DC60-90V or DC40-70 can work normally, output voltage is 5~7 times of input voltage. Output voltage changes according to input voltage so that solar pump inverter can track the maximum power of PV arrays.

Solar DC voltage booster

LV40-70( 40 to 70VDC input, 240V to 420VDC output)

LV60-90 ( 60-90VDC input, 480V to 720VDC output)

This product has high efficiency. When power is under 200w, the efficiency is under 90%; when power above 200W, the efficiency can reach above 90%. Efficiency increase with power increase, maximum efficiency can reach 95%. Normally, this product doesn’t need operation, normal working only need to connect the input wire and output wire correctly.

66VDC input, output 350VDC, for 3 phase 220VAC pumps

66VDC input, output 350VDC, for 3 phase 220VAC pumps

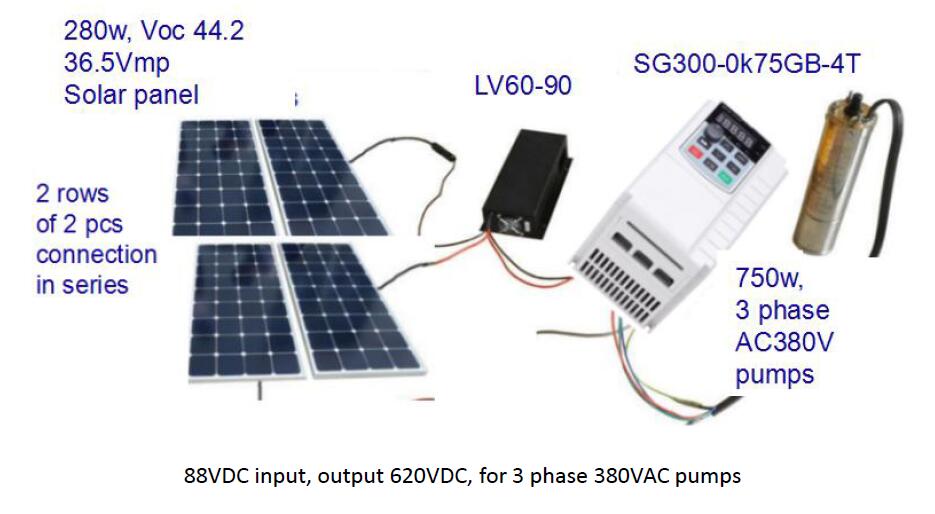

88VDC input, output 620VDC, for 3 phase 380VAC pumps

Application:

Low voltage drive device for small solar pump system, set an example of LV60-90, Currently, among application of 3-phase solar pump system, the inverter minimum DC input voltage is 450V. In order to meet the voltage of solar pump inverter, many solar panels are needed. In some real application, the power of the water pump is small, and the power of several solar panels is enough for solar pump inverter to drive the pump. But the voltage of several solar panels is not enough to meet the voltage of solar pump inverter, so cause using more solar panels. In this case, much power of solar panels is wasted and it makes the cost of whole system very high.

Now our company has developed a new technology to solve this problem. We manufacture low voltage boost device (Model: LV60-90) to convert low DC voltage to high DC voltage to meet the voltage of solar pump inverter. Meantime, this new system avoids the danger of high DC voltage from solar panels

Make sure the DC voltage from solar panel meets input voltage of low voltage drive device.

For example, if your pump is 750W, 3phase, 380v, use our inverter 750W ( 3phase, 380v,DC input voltage range is 450v-750v) it need minimum 1120W solar panels . We use 280w/pcs solar panel, vmp 37V, voc 44V. Total need 4pcs, 280w solar panel.

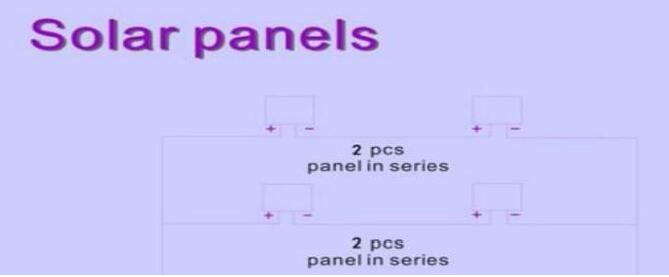

Solar panel connecting as below: 2pcs connecting in series, total 2groups

So, total vmp 37V *2=74V (60-90V), voc 44V*2=88V (60-90V), both vmp and voc should in the range 60v-90v)

Make sure total vmp and voc voltage from solar panels between 60-90V.

Ⅰ. Installation Notes:

1. In order to ensure good convection cooling effect, the device must be mounted vertically, and leave at least 10cm space on the top and on the bottom.

2. The device should be installed indoor with vents or scavenging arrangement. Do not install under direct sunlight.

3. During installation, please do not fall drilling residual fabrics into cooling fins or fans of inverter, to prevent the impact of cooling. 4. If find the device damage or short of parts, can’t be installation, otherwise may cause fire accident.

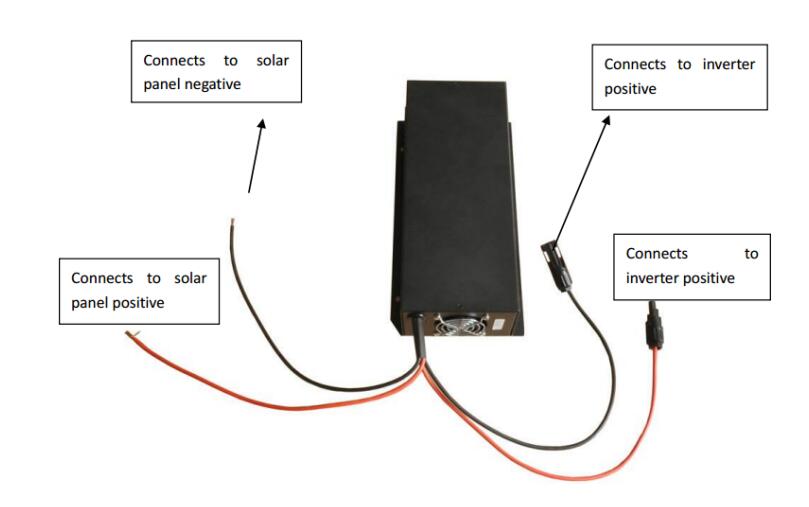

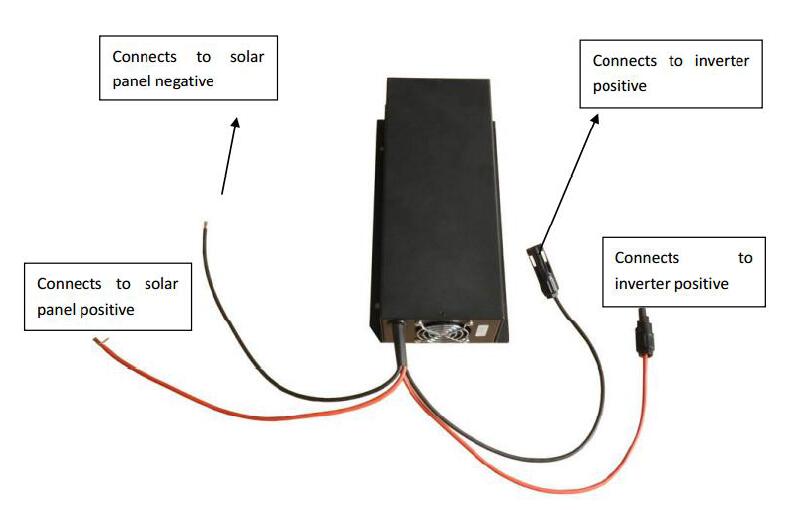

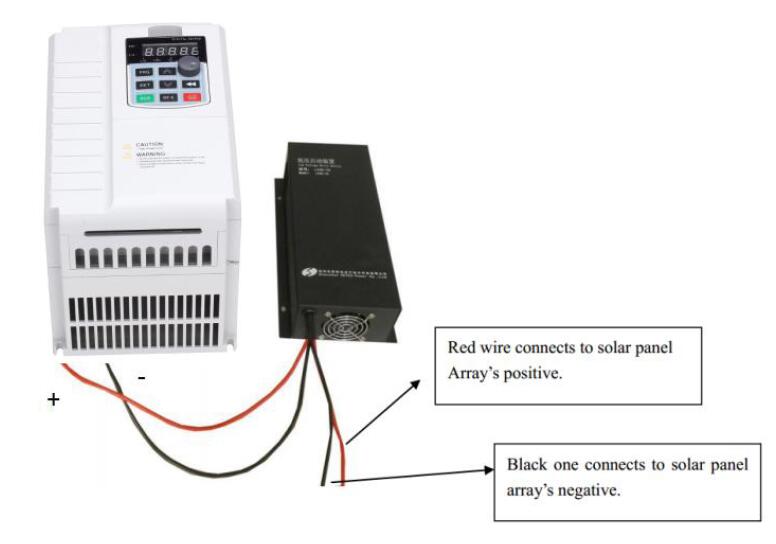

Ⅱ. Wiring

1. Wiring must be carried out by qualified electrical professionals, or it may cause electric shock or fire.

2. Before wiring, make sure the input power has been cut off, otherwise may cause electric shock or fire.

3. The PV array selection should be reasonable, otherwise it may damage the device. 4. Do not change the wiring in the power, otherwise there is a risk of electric shock.

Ⅲ. Model Definition

Ⅳ. Checking before installation

| Checking items | Checking method |

| Whether consistent with the ordered products | Checking products brand and label |

| Whether there is breakage, shedding | Checking the overview of whole product |

| Whether screws and other fastening parts are loose | If necessary, using screw knife for checking |

Prev:end Next:end

We are focusing on motor control over than 20 years---famous manufacturer of AC motor drive

Item:0

Item:0