Tel:86-0755-84186866,

MP:86-18038034988

Mail:service@kewoinverter.com Skye:gary.yu88

AS850Z AC Servo Drive for PMSM of IMM

AS850-Z Hybrid Servo Drive For PMSM Of Injection Molding Machine

AS850Z series servo drive for permanent magnet synchronous motor (PMSM), is KEWO own developed hydraulic electric servo drive system for injection molding machine energy saving. It has following advantage, high energy saving, high power factor, quick response and high accuracy control, etc. AS850Z has powerful overload capability even under low speed, 180% rated torque for 30s under 0 speed is possible to ensure good pressure keeping ability.Output frequency range: 0 to 400Hz.

Input voltage: 3 phase 380V±15%, 2.2kw to 90kw

Pressure signal reference: external analog 0-10V, 0-1A.

Protection function: Input phase missing, input under voltage, over voltage, over current, over load, over heat, external disturbing .

Cooling method: force cooling

Mount: Wall mount

Function features

Energy saving: up to 60% energy saving compare to traditional fixed pump system. 75% is possible be achieved according to difference injection condition.

Lower oil temperature: reduce 5-10 degrees

High repeated accuracy: To achieve high accuracy flow and pressure control

Long pressure holding time: It is favorable for big wall thickness.

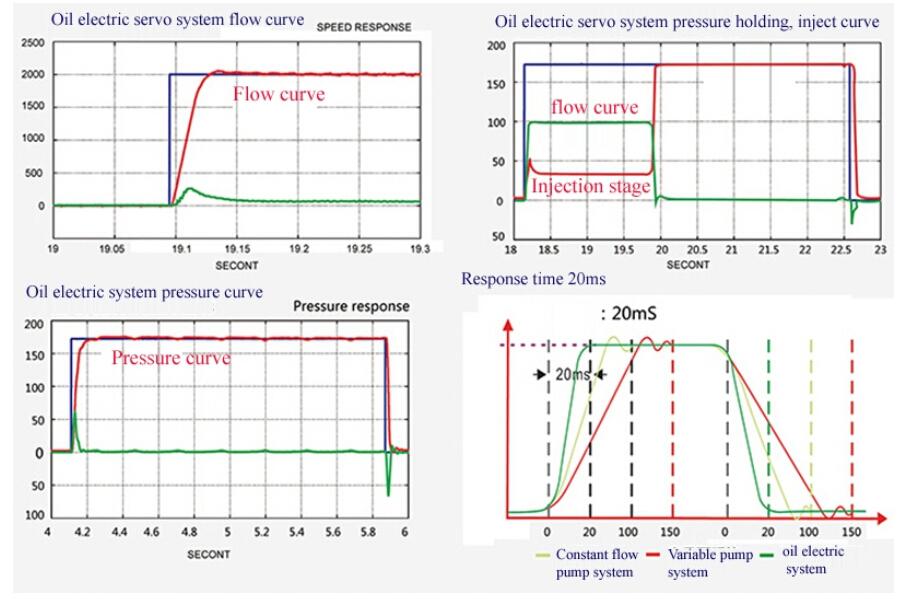

Quick response: frequency response up to 50ms.

AS850Z AC Servo Drive Enhanced Features:

1. Design the signal correction algorithm and match to work high performance under low speed characteristic to solve the creep problem of IMM. Because his given signal reference is nonlinearity characteristic.

2. Due to switching frequently in flow control mode, so we adopt fuzzy control to realize smooth switch of flow and pressure control.

3. Adopt flow control with pressure compensation to eliminate effect of flow estimate accuracy.

4. Adopt noise control method to reduce the fluctuation of output pressure of oil pump.

5. Monitoring temperature of motor and drive in whole journey, parameters adjusting in real time

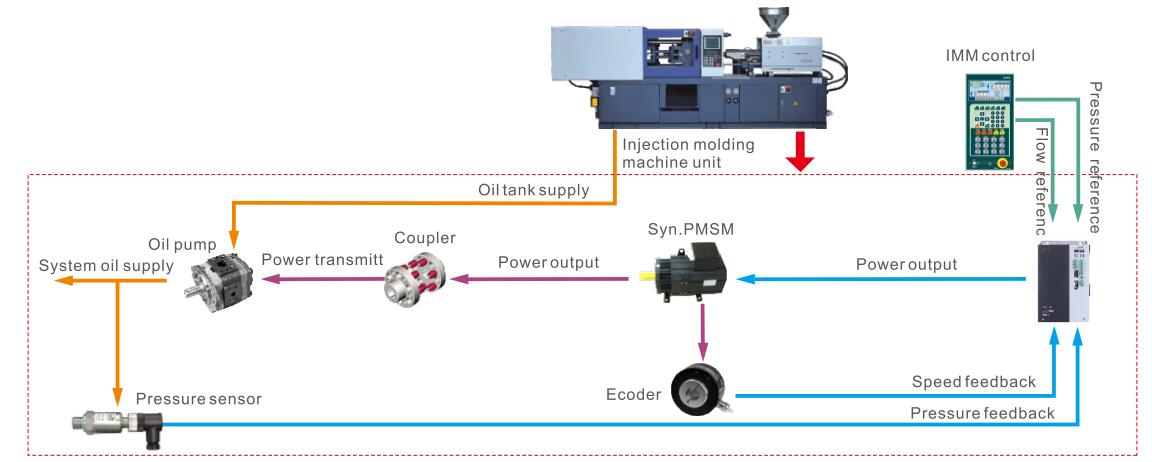

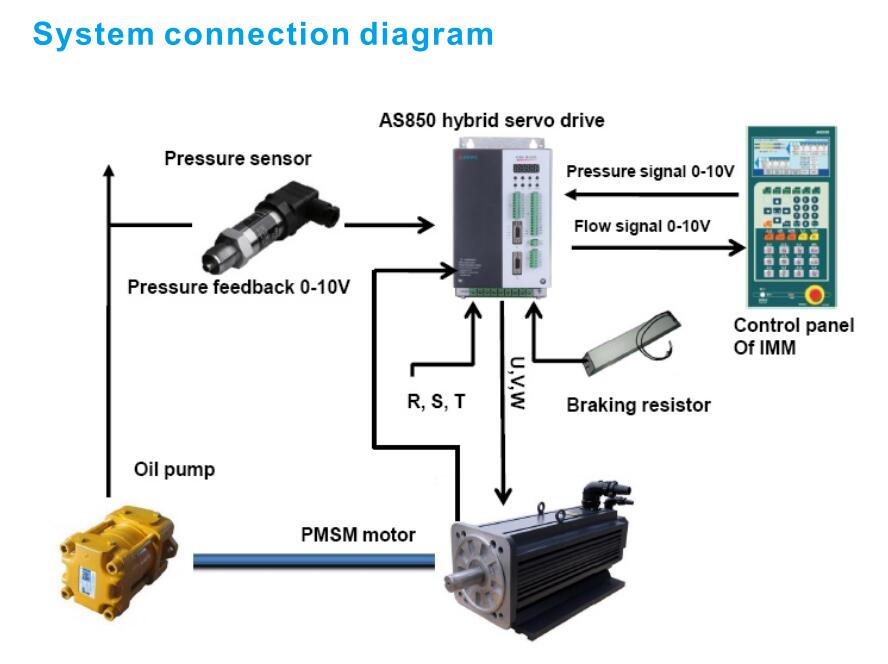

System connection for energy saving with hybrid servo drive

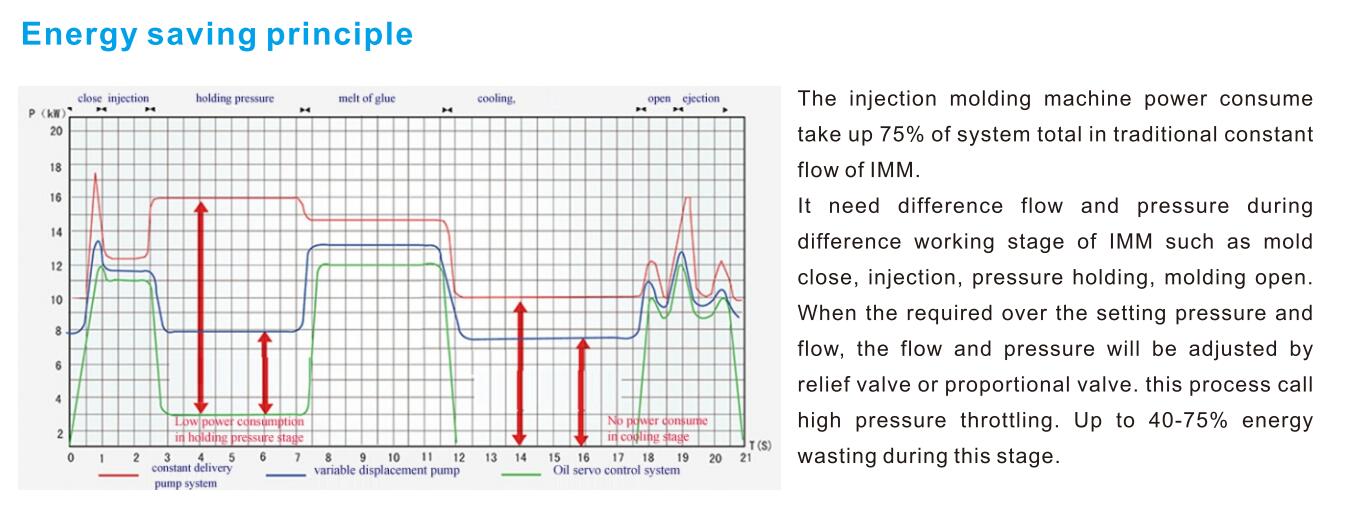

Energy saving comparison diagram

The injection molding machine power consume take up 75% of system total in traditional constant flow of IMM.

It need difference flow and pressure during difference working stage of IMM such as mold close, injection, pressure holding, molding open. When the required over the setting pressure and flow, the flow and pressure will be adjusted by relief valve or proportional valve. this process call high pressure throttling. Up to 40-75% energy wasting during this stage.

Oil servo drive system performance.

System curve of Kewo AD850Z servo drive in IMM application

AS850Z AC Servo DriveTechnical data

| Items | Description | |

| Input | Rated voltage range | 3 phase 380V±15% |

| rated frequency | 50/60Hz | |

| Output | rated voltage range | output 0 to 380V |

| rated frequency | 0.00 to 400.00Hz | |

| mounting | wall mounting with IP20 | |

| Cooling method | force cooling | |

| Encoder | Rotary transformer | |

| Pressure reference | External analog signal (0-10V) | |

| Flow reference | External analog signal (0-10V) | |

| pressure feedback | External analgo ( 0-10V or 4-20mA) | |

| Control input | 9 channel insulation input | |

| control output | 3 channel insulation input | |

| analog output | 1 channel output | |

| Protection function | Phase missing input, under voltage input, over voltage input, over current, overload of drive, overheat of motor, external interference encoder fault. | |

| Display | current output display, current rotation, current output current, output voltage, fault alarm, operation parameters, running status. | |

| using place | Indoor, no sunlight exposure, no dusty, corrosive atmosphere, no flammable gas, no water dip and not salt. | |

| Environment temperature | "-10 ℃ to 50℃ | |

| Environment humidity | 90% below( no condensation) | |

| shock intensive | 0.5g( acceleration) below | |

| altitude | 1000 below. | |

| Items | Description | |

| Input | Rated voltage range | 3 phase 380V±15% |

| rated frequency | 50/60Hz | |

| Output | rated voltafe range | output 0 to 380V |

| rated frequency | 0.00 to 400.00Hz | |

| mounting | wall mounting with IP20 | |

| Cool method | force cooling, fans control is available | |

| Encoder | Rotary transformer | |

| Pressure reference | External analog signal (0-10V) | |

| Flow reference | External analog signal (0-10V) | |

| pressure feedback | External analog ( 0-10V or 4-20mA) | |

| Control input | 9 channel insulation input | |

| control output | 3 channel insulation input | |

| analog output | 1 channel output | |

| Protection function | Phase missing input, under voltage input, over voltage input, over current, overload of drive, overheat of motor, external interference, encoder fault. | |

| Display | current output display, current rotation, current output current, output voltage, fault alarm, operation parameters, running status. | |

| using place | Indoor, no sunlight exposure, no dusty, corrosive atmosphere, no flammable gas, no water dip and not salt. | |

| Environment temperature | "-10 ℃ to 50℃ | |

| Environment humidity | 90% below( no condensation) | |

| shock intensive | 0.5g( acceleration) below | |

| altitude | 1000 below. | |

Model selection

| Servo drive model | Input voltage | Rated output power (KW) | rated input power (A) | Rated output current (A) | braking resistor power selecting | braking resistor (Ω) | Braking unit |

| AS850Z4T017 | 3 phase 380V | 7.5 | 20.5 | 17 | 1000 | >90 | built in |

| AS850Z4T025 | 11 | 26 | 25 | 1000 | >40 | ||

| AS850Z4T032 | 15 | 35 | 32 | 1000 | >32 | ||

| AS850Z4T037 | 18.5 | 38.5 | 37 | 2500 | >32 | ||

| AS850Z4T45 | 22 | 46.5 | 45 | 2500 | >16 | external connect | |

| AS850Z4T60 | 30 | 62 | 60 | 2500 | >16 | ||

| AS850Z4T75 | 37 | 76 | 75 | 5000 | >8 | ||

| AS850Z4T91 | 45 | 92 | 91 | 5000 | >8 | ||

| AS850Z4T112 | 55 | 113 | 110 | 5000 | >8 | ||

| AS850Z4T150 | 75 | 157 | 150 | 5000 | >8 | ||

| AS850Z4T175 | 93 | 180 | 175 | 5000*2 | >8*2 | ||

| AS850Z4T210 | 110 | 214 | 210 | 5000*2 | >8*2 | ||

| AS850Z4T250 | 132 | 256 | 250 | 5000*2 | >8*2 | ||

| AS850Z4T300 | 160 | 307 | 300 | 5000*2 | >8*2 |

Application:

1. Injection molding machine

2. pressure die casting machine

3 . brick machine

4. shoes machinery

5. Pressing machine

6. Aluminum extrusion machine

7. Hydraulic, CNC punching machine

8. Civil engineering machine

9. Other hydraulic machinery

Item:1

Item:1