Tel:86-0755-84186866,

MP:86-18038034988

Mail:service@kewoinverter.com Skye:gary.yu88

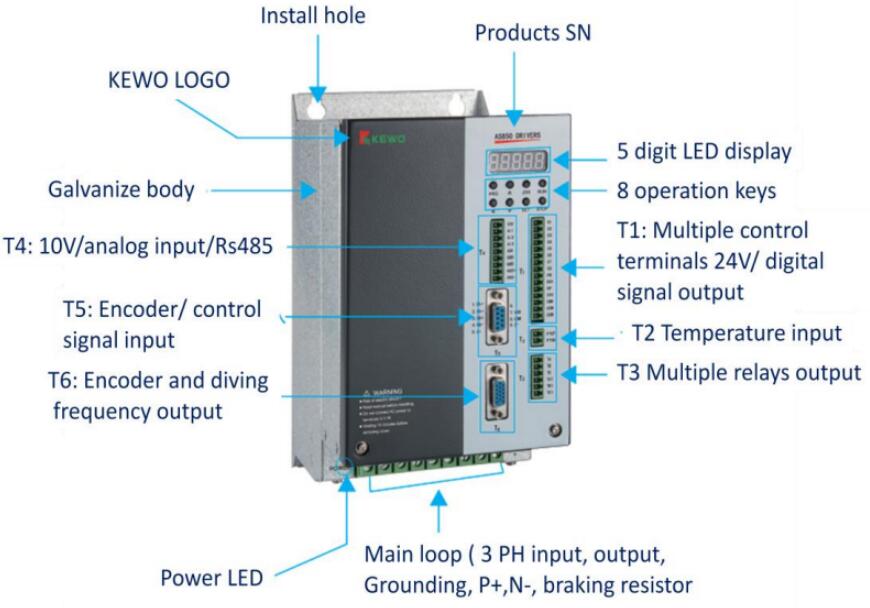

AS850T Spindle AC Servo Drive

AS850T Spindle AC Servo Drive ( Spindle Frequency Inverter)

AS850T is a new tailor made spindle controlling frequency inverter (servo drive) for CNC, machining center, packing, textile, etc. It can achieve to high accuracy speed, torque and position control through close loop servo control, which based on brand new hard ware and soft ware platform.

Perfect performance and powerful function is your machine best selection.

Production Name: AS850T Spindle Servo Drive ( Spindle Servo Frequency Inverter)

Output Frequency Range: 0 To 1000Hz.

Input Voltage: 3 Phase 380V±15%, 2.2kw To 75kw.

Control Mode: Current/Flux Vector Control, Close Loop Vector Control

Protection Function: Over Current, Over Voltage, Power Module Overheat, Under Voltage, Over Load, Input/Output Phase Missing, Motor Short Circuit Protection.

Cooling Way: Force Cooling.

Mounting Way: Wall Mounting.

Function: Speed control, torque control, position control, synchronous pulse control.

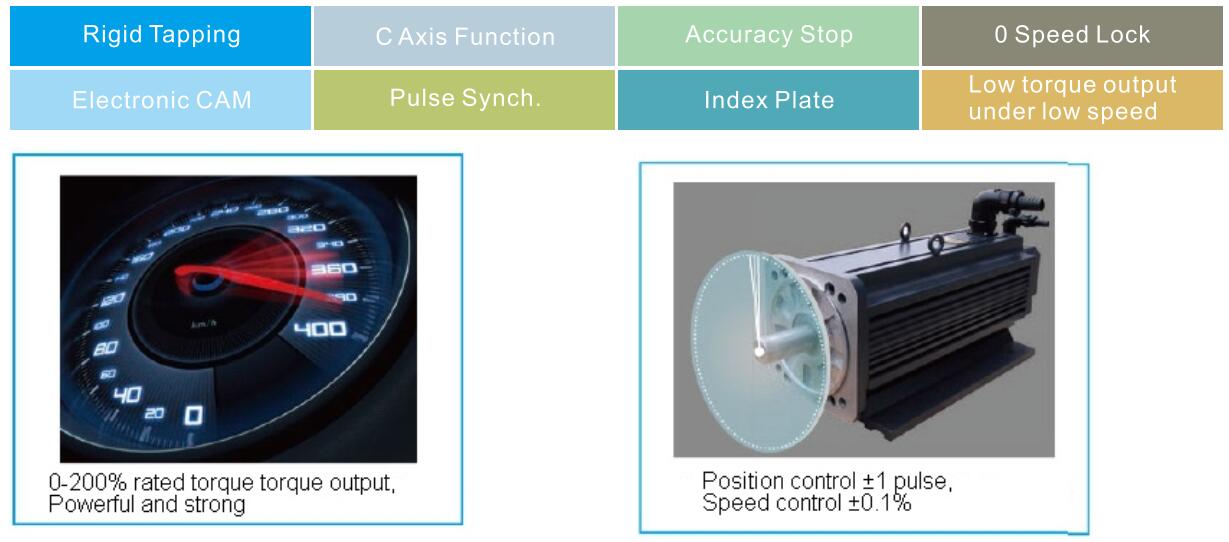

Function features

Software function

| Function | Application | Purpose | function describe |

| points positioning | mechanical transmission | auto process control | The servo motor will run when receiving a command, and move to setting point. When arriving the set point, it will stop and sent a signal back |

| reciprocating position running | mechanical transmission | auto process control | Perform reciprocating movement between two points, the speed can be set. |

| multiple points positioning | mechanical transmission | auto process control | Up to 256 points can be set. When corresponding input signal is valid, motor will move to that point. |

| synchronous driving | mechanical transmission | synchronous speed control | The motor speed swill synchronize with the input pulses, the synchronize ratio can be set. Used in print and textile. Etc filed |

| torque control | pressing machine | output torque adjustable | The motor torque can be adjusted by analog input or communication method. Ensure every motor has the same torque |

| cut to length | transverse cutter, | auto to realize fixed length cutting | The drive will measure the cutting length by external encoder, and calculate the initial point, it will activate cutting when arriving the cutting length. |

| parallel drive | roller rail | to realize same output | To achieve the same output for every motor when multiple drives serving a load by communication mode. |

Main features of AS850 Servo Drive

Points positioning control

The pulse can be set by functional code, even no pulse command, the position control of fix route can set by external terminal as well.

.jpg)

Control mode of AS850 AC Servo Drive

Technical specification

|

Technical Specification |

||

|

Input |

rate voltage |

380V+ 10% -15% |

|

rated frequency |

50/60Hz |

|

|

Output |

output voltage |

0-380V |

|

output frequency range |

0-1000Hz |

|

|

Control feature |

control mode |

current/flux, close loop vector control |

|

starting torque |

0.0Hz 180% |

|

|

torque limit |

0-200% rated motor torque |

|

|

torque control accuracy |

±5% |

|

|

speed control ratio |

"1:5000 |

|

|

speed control accuracy |

±0.1% |

|

|

position accuracy |

±pulse no.s |

|

|

accel./decel. control |

0.05 to 3000Hz |

|

|

braking mode |

Dynamic braking, built it braking unit |

|

|

over load capability |

150% rated load for 3 min, 200% for 3s |

|

|

analog input |

3 ways, -10V to 10V, 0-10V/4-20mA |

|

|

analog output |

0-10V/4-20mA |

|

|

Programmable digital input |

9 ways digital input, NPN/PNP acceptable |

|

|

Programmable external pulse input |

pulse+ director, quadrature pulse |

|

|

protection function |

over current, over voltage, overheat, under voltage, phase missing, motor short circuit. |

|

|

environment |

temperature |

"-25℃to 45℃ |

|

humidity |

< 90% RH, Non-condensate |

|

|

Vibration |

below 20Hz, 1G, 20 to 5Hz,, 0.2G |

|

|

Heat dissipation |

force cooling |

|

|

protection grade |

IP20, |

|

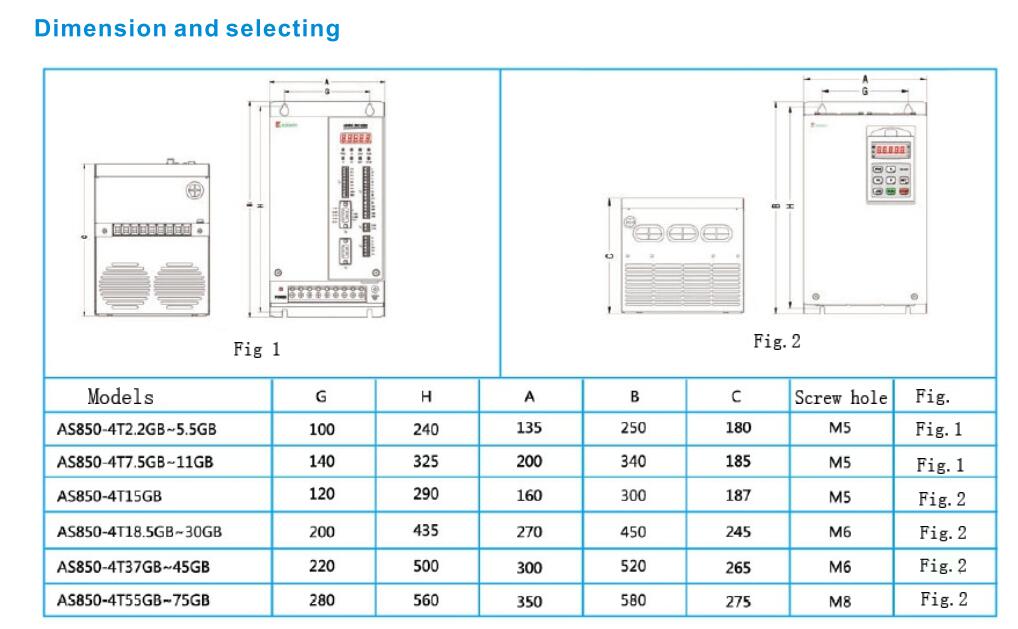

Dimension and selecting.

Wiring diagram

1. 8 digital input,

2. built in Can bus, built it PG card, Modbus card

3. 3 analog input, 2 collector output, 2 relay output, 1 analog output. PT100 temperature sensor connection

.jpg)

Item:1

Item:1